Nickel based high-temperature alloys are metal materials with excellent high-temperature performance, mainly used in the preparation of combustion chambers, turbine blades, guide vanes and other components of aerospace engines. As holes for connecting and fixing various components of aerospace engines, they need to meet high precision requirements.

The low thermal conductivity of nickel based alloys makes it difficult for the heat generated during cutting to dissipate, resulting in high temperatures at the contact point between the tool and the workpiece, which exacerbates tool wear

During the drilling process of nickel based high-temperature alloys, chips are not easily broken and often wrap around the tool, making it difficult to discharge smoothly. This situation can easily cause the tool to suddenly get stuck during the mach

Nickel based alloys are prone to work hardening during cutting, which increases the difficulty of cutting and further accelerates tool wear;

Nickel based alloys typically contain elements such as chromium, molybdenum, and tungsten, which react chemically with tool materials at high temperatures, leading to wear and damage of the tool materials;

Nickel based alloys have high toughness, making it easy for chips to deform and difficult to break during cutting, resulting in greater cutting and thermal stress on the tool and exacerbating tool wear;

Commonly used hard alloy cutting tools wear out quickly when processing nickel based alloys;

Although tool coating can improve the wear resistance and adhesion resistance of tools, due to the high temperature during the processing of nickel based alloys, the coating is prone to damage and difficult to last.

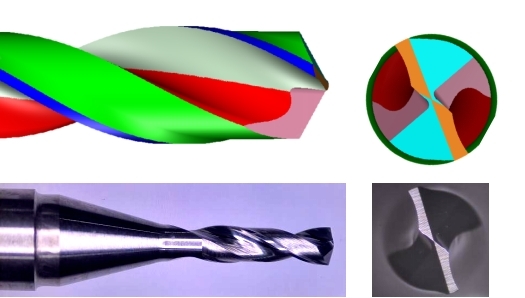

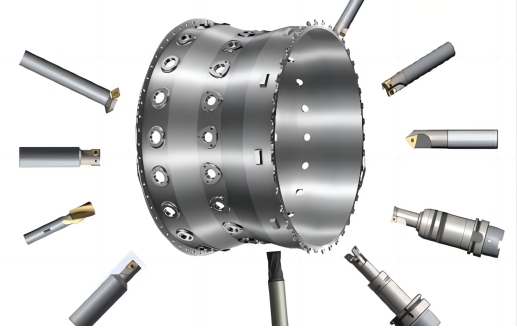

In response to the drilling difficulties of nickel based high-temperature alloys, our company designs drill bits from the following perspectives